ISG news

The Latest at ISG

Learn how ISG is setting the pace in the industry. From big picture thinking to granular details captured with our innovative technology we don’t slow down. Instead, we continually explore new ways that we can make tomorrow better than today.

.webp)

Navigating the MS4 Permit Program: How ISG Supports Communities Every Step of the Way

The management of stormwater runoff is a pressing concern for cities across the nation, and the Municipal Separate Storm Sewer System (MS4) permit program is a critical framework designed to protect water quality and our natural resources.

Environmental Firm to Host Second Annual Southern Minnesota Lake Resources Conference

ISG will host the second annual Future of Southern Minnesota Lakes Conference at the Mayo Clinic Health System Event Center in Mankato, Minnesota. The conference will open on Friday evening, April 12, with a fireside chat featuring writer and host of the television show "Minnesota Bound," Ron Schara. The evening is an exclusive opportunity for conference attendees to share stories about Minnesota’s natural resources and learn from one another in a relaxed atmosphere.

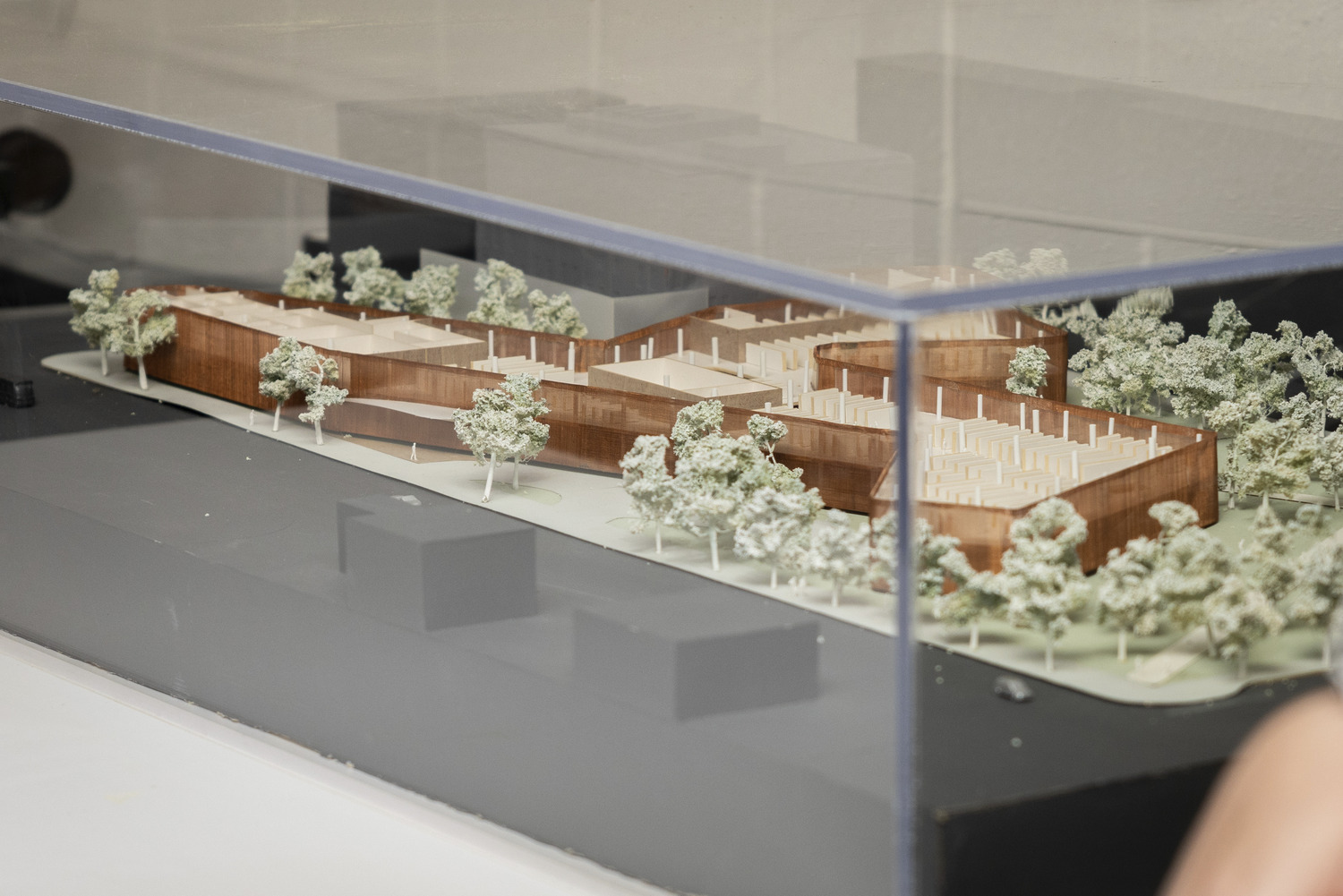

Shared Visions, Shared Spaces: Making Use of Public and Private Partnerships for New Library and Housing Development

New Richmond, Wisconsin is on track to expand its library and housing options through a joint effort of the City, school district, and a private developer.

Optimize Maintenance + Reveal Opportunities with Facilities Assessments

The Clay County Board of Supervisors (County) knew they needed to address facility repairs in their Administration Building, Courthouse, and General Services Center. While maintaining public buildings does not generate excitement, County leaders recognized that deferring upkeep of public facilities can cost more in the long run if left unaddressed and may result in limiting other more impactful projects.

LET'S chat.

.svg)